€171.39*

Available in 14 days, delivery time 7-10 Tage

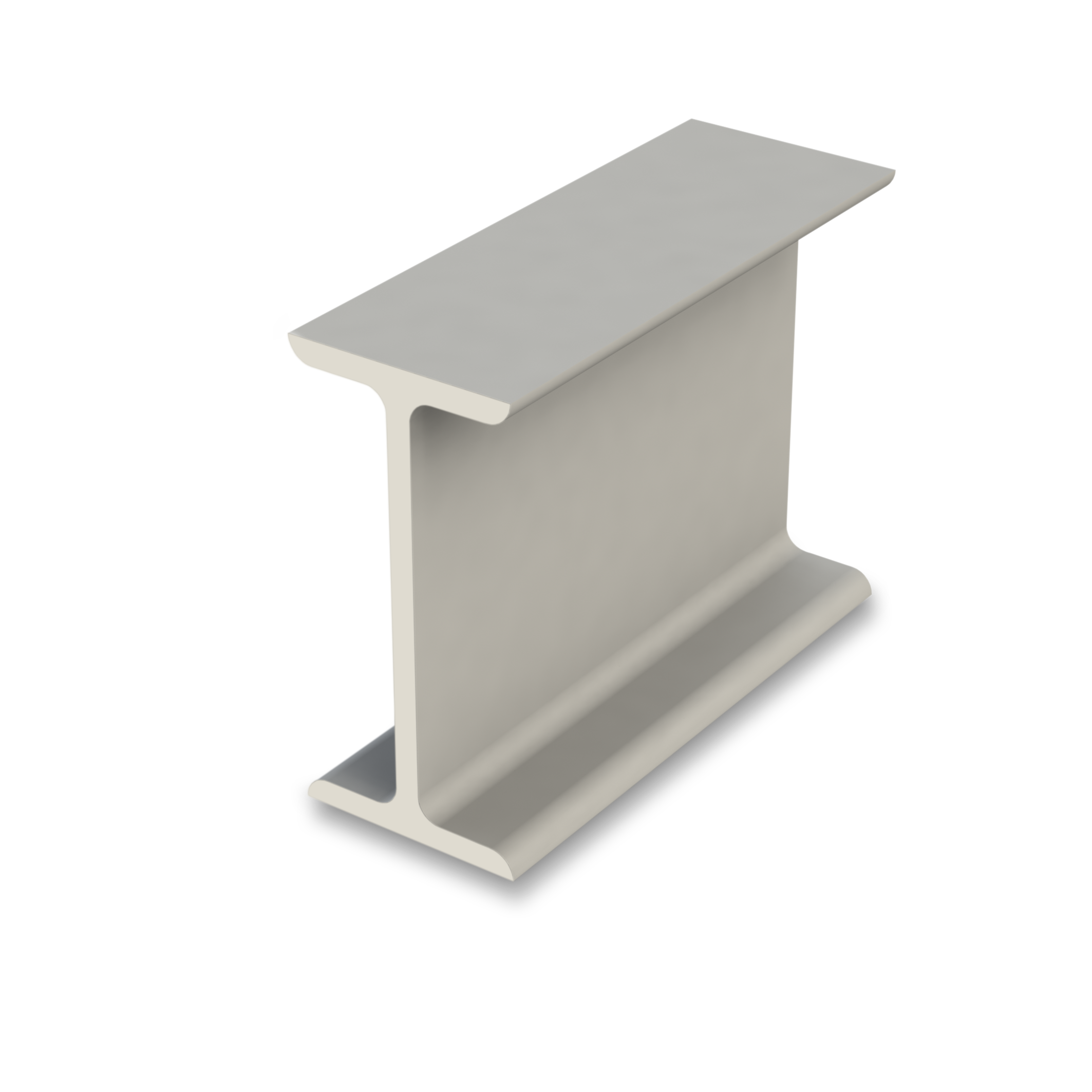

Our GFK H-profile, made from a composite of GFK and resin reinforced with fiberglass, provides the ideal solution for applications seeking robust and durable materials. These pultruded profiles, manufactured by Fibrolux, are vital for constructing structural profiles and are used in various environments, including galvanic, chemical, and refining industries, water treatment, cooling and cooling towers, offshore facilities, railways, subway tunnels, and construction, especially in corrosive environments. They are characterized by high mechanical performance, low weight, flexibility, and electrical insulation.

GFK H-profiles are UV-resistant and maintain their stability and color even in sunlight. Compared to steel, they are lighter, making them particularly suitable for mechanical and electronic engineering, where high load-bearing capacity with low weight is required. These profiles are easy to install, maintenance-free, and offer exceptional mechanical strength, corrosion resistance, and thermal insulation.

Profile dimensions vary and are available both from stock and custom-made. Selected stock dimensions are available in gray with a standard surface. Various physical and mechanical properties, such as density, dielectric strength, water absorption, surface resistance, loss factor, thermal expansion coefficient, and thermal conductivity, are specified.

Application Areas:

- Electrical and Electronic Engineering

- High Voltage Primary Systems

- Low Voltage Power Distribution Systems

- Backup Power Systems during (Re)Construction

- Mechanical Engineering

- Medical Technology

- Marine Technology

- General Construction

| Glass percentage: | approx. 60% |

|---|---|

| Heat resistance: | from -100°C to +180°C |

| Interlaminar shear strength: | 25 - 35 MPa |

| Material: | Glasfaserverstärktes Polyesterharz |

| Material type: | Fleece, Mat |

| Tolerance of length: | ± 5 mm |